ground solar brackets of Comprehensive analysis of weather resistance and corrosion resistance

Material selection and performance

Galvanized steel

Surface hot-dip galvanizing treatment can form a zinc protective layer, suitable for general atmospheric environments, but in marine climates or acid rain environments, attention should be paid to the thickness of the zinc layer (≥ 80 μ m) and process quality.

The corrosion resistance of hot-dip galvanized brackets can reach 15-20 years, and they have wear resistance and high temperature strength, but the cost is high and transportation is limited.

Aluminum alloy

After anodizing treatment, a dense oxide film is formed, which has excellent corrosion resistance, lightweight and high strength, and is suitable for installation in complex terrains.

Attention should be paid to the alloy composition (such as 6063-T5, 6061-T6) and the quality of the oxide film to improve weather resistance.

Stainless steel

The 304/316L model has the best corrosion resistance and is suitable for high salt spray and marine environments, but the cost is relatively high.

Core indicators of weather resistance

Corrosion resistance capability

Galvanized steel can meet the requirements in conventional environments, but in saline soil areas, it is necessary to increase the thickness of the zinc layer or use stainless steel.

Surface coatings (such as PVDF, powder coating) can resist ultraviolet radiation and chemical erosion, extending their service life.

Wind resistance performance

The structural design needs to meet the load requirements of wind speed of 40-50m/s, achieved by strengthening the connection nodes and foundation stability.

UV resistance and temperature resistance

The material needs to withstand temperature changes from -40 ℃ to 80 ℃, and the galvanized layer or oxide film should avoid high-temperature embrittlement.

Design and process optimization

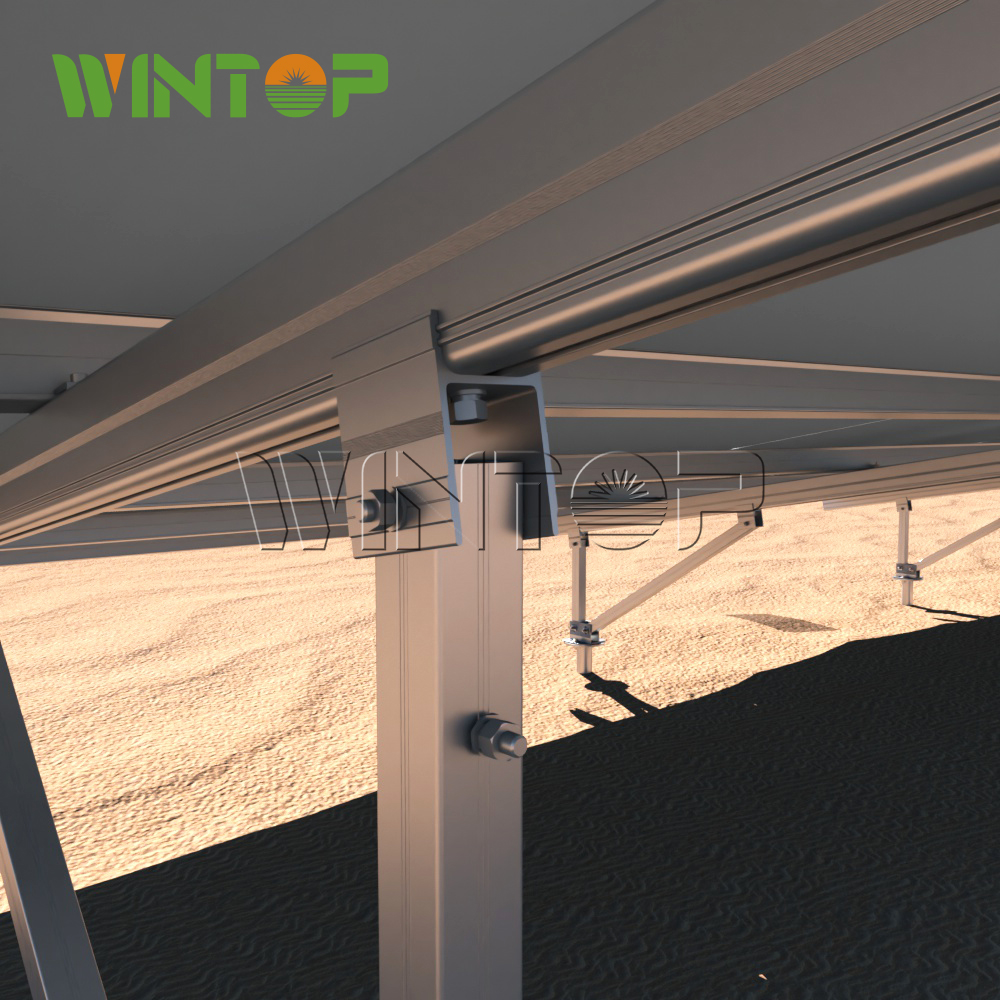

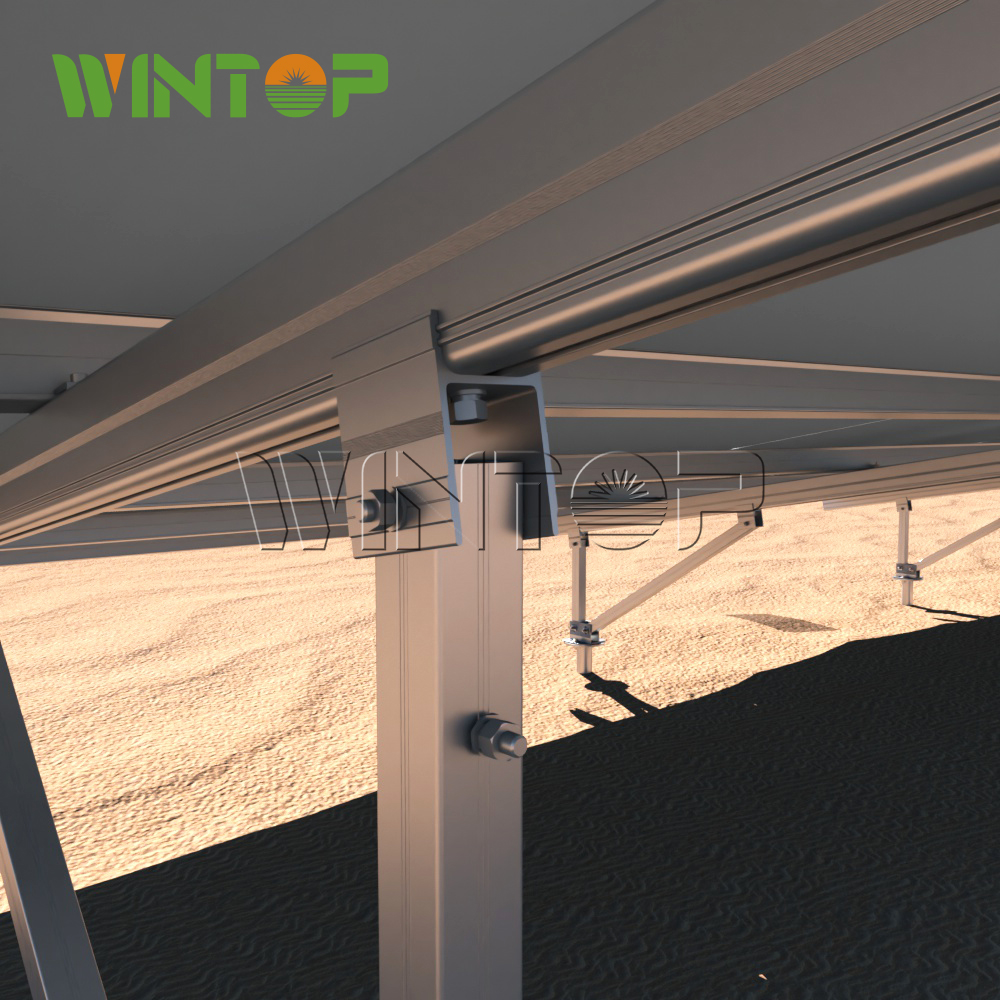

Structural Design

Adopting a tilted design to reduce water accumulation and avoid corrosion blind spots; Optimize the self weight of the support to reduce foundation pressure.

Key parts (such as purlins and columns) need to be strengthened with anti-corrosion treatment to prevent deformation or corrosion.

Anti corrosion process

The hot-dip galvanizing process requires controlling the uniformity of the coating to avoid damage during transportation or installation.

The welding area requires secondary anti-corrosion treatment (such as coating with epoxy resin).

Special environmental response

Saline landform

Soluble salts in soil are prone to electrochemical corrosion, so stainless steel or increased galvanized layer thickness (≥ 120 μ m) should be used, and salt deposits should be regularly cleaned.

Areas with high humidity/acid rain

Prioritize aluminum alloy or stainless steel, and fill the gaps with sealant to isolate water vapor.

Installation and maintenance requirements

Installation and maintenance requirements

During installation, avoid scratching the galvanized layer and use bolt connections instead of welding to reduce material damage.

Regularly inspect the corrosion and coating peeling of the bracket, and promptly repair the paint or replace the components.

Quality Control Standards

The material must comply with the standard GB/T 13912-2020 "Hot Dip Galvanized Coating on Steel Articles with Metal Coating", and the thickness of the zinc layer must meet the standard.

Aluminum alloy brackets must meet the weather resistance requirements of GB/T 5237-2017 Aluminum Alloy Building profiles.

Through material selection, structural optimization, and regular maintenance, ground solar brackets can achieve a service life of over 25 years and adapt to various harsh environments